I have over 3 years of professional work experience spanning multiple disciplines. There’s nothing I’m not capable of learning and understanding.

Project Manager – Eli Lilly and Company

I evaluate, manage, and execute requirements for large capital projects ($50MM+). Specifically, manufacturing facilities that produce medicine for patients.

Bachelor of Science: Mechanical Engineering, Aerospace Minor – Michigan State University Honors College

Aerodynamics & Fluid Mechanics, Capstone Project Lead: MSU Solar Car Body Design – Michigan State University

I led my senior capstone team designing a new body for MSU’s Solar Racing team. We utilized fundamental principles of aerodynamics, boundary layer theory, and other fluid mechanics principles to produce a design that significantly improved aerodynamic performance through drag reduction. 4.0 in the class! Here’s the final report:

Aerospace Engineering: Rocketry – Maru-A-Pula

As for the competition? Our school came first, and I won first place for individuals. This experience was some of the most fun I’ve ever had. The launch catastrophes, the shattered windows, the almost blown off fingers, the melted dust bins, the raging teachers, the late nights, and the overwhelming stress. I loved it so much that I did it again the year after but with a different project. The lack of resources required for my ventures provided challenging and realistic problems to solve. Instead of buying everything, I had to seek raw materials, machinery, contractors and budget my expenses much like in industry. I learned a lot of vital skills in the process that have no doubt proven useful in university and I’m sure will beyond. Particularly patience, clear and effective communication, resilience, teamwork, problem solving and negotiation techniques such as rapport building and active listening.

Renewable Energy, Development Engineering & Manufacturing: Thin film & Monocrystalline Solar Panels – First Solar, Inc.

At First Solar, I was involved in lots of different projects. On the development engineering finishing team, I validated and optimized a novel ultrasonic welding process for solar modules. I utilized JMP statistical analysis software to analyze and interpret critical testing data, enabling data-driven decision-making for process enhancements. I also aided in assembly and testing of new tandem solar modules, incorporating monocrystalline and thin film technology for improvement in conversion efficiency.

Web Development, Social Media Management & Sponsorship Coordinator: Secretary & Communications Chair – Michigan State University Chapter of the National Society of Black Engineers.

I led our social media rebrand transitioning from a fragmented naming system to a streamlined, unified approach. Redesigned chapter website (nsbemsu.org), ensuring user friendly design and up-to-date content and Solicit sponsorships and support from industry-leading companies like SpaceX to support chapter.

Research, Electrochemistry & Additive Manufacturing: Boron Doped Diamond and Carbon Fiber Electrodes – Fraunhofer USA, Inc.

This is the flow cell setup that we used to test our electrodes. It serves to simulate conditions of the brain. We pumped a solution that mimics brain conditions into the white 3D printed part and test electrode sensitivity to various neurotransmitters like dopamine and serotonin.

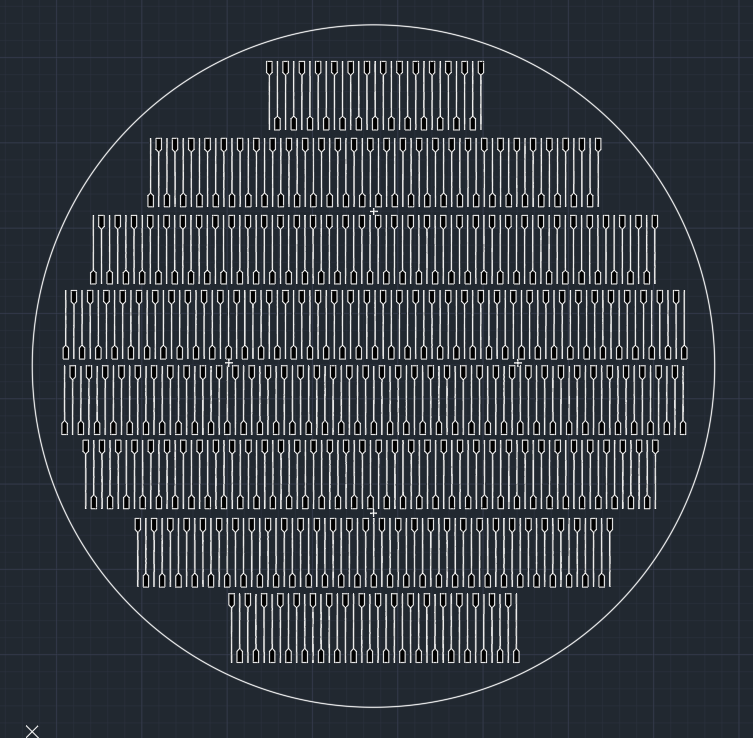

This is an AutoCAD sketch I made that we use as a template to grow diamond electrode needles at Fraunhofer USA, Inc.

We tested for dopamine by cycling a voltage applied to the electrode from -0.3V to +1.4V and measuring current response. At around -0.1V, the dopamine is reduced resulting in the negative peak shown. At around +0.7V, the dopamine is oxidized resulting in the positive oxidation peak. One of my carbon fiber electrodes successfully measured dopamine in vivo in a rats brain aiding in Parkinson’s research at the Institute for Quantitative Health Science and Engineering at MSU.

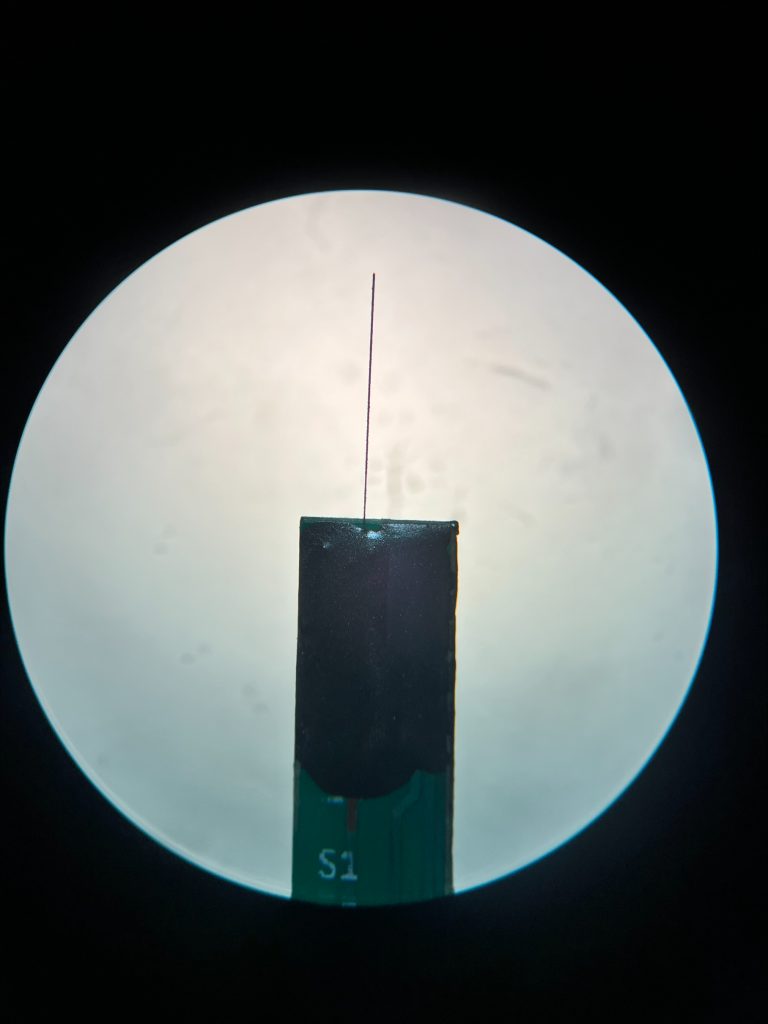

These are the boron doped diamond electrode needles I assisted in fabricated. We were investigating them as a replacement to industry standard carbon fiber electrodes as they last longer. Carbon fibers etch away as they are used and eventually need to be replaced. Boron doped diamond is more stable. Dopamine in the brain is hard to detect because it has such low concertation (it’s of the order nanomolar per Liter) so sensitivity is important. We ran experiments to increase the sensitivity while maintaining its durability. I ran long term experiments evaluating different coatings utilizing fast scan cyclic voltammetry, A.C. Impedance spectroscopy and tested their effects on neurotransmitter sensitivity. I also contributed to a research paper with this data.

Biosensors Research Publication: Experiment Contributor – Fraunhofer USA, Inc.

https://www.mdpi.com/2079-6374/13/6/576

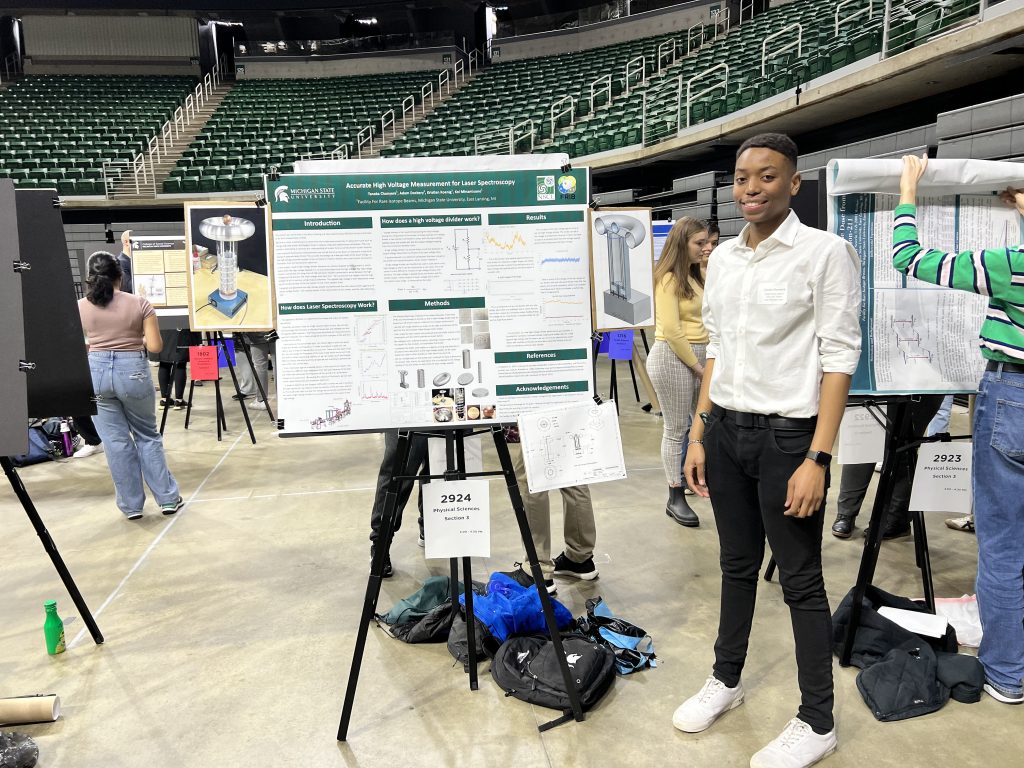

Research, Electrical Engineering & Nuclear Physics: High Voltage Divider (HVD) – Facility For Rare Isotope Beams

As part of the Wielenga Research Scholars program at Michigan State University (with a $5,000 grant awarded), I joined Dr. Kei Minamisono’s team at the BEam COoling and Laser Spectroscopy (BECOLA) facility at the Facility For Rare Isotope Beams (FRIB).

Accurate Knowledge (at a few ppm level) of the beam energy i.e., the high voltage potential applied to the beam is crucial to deduce very small nuclear structure information.

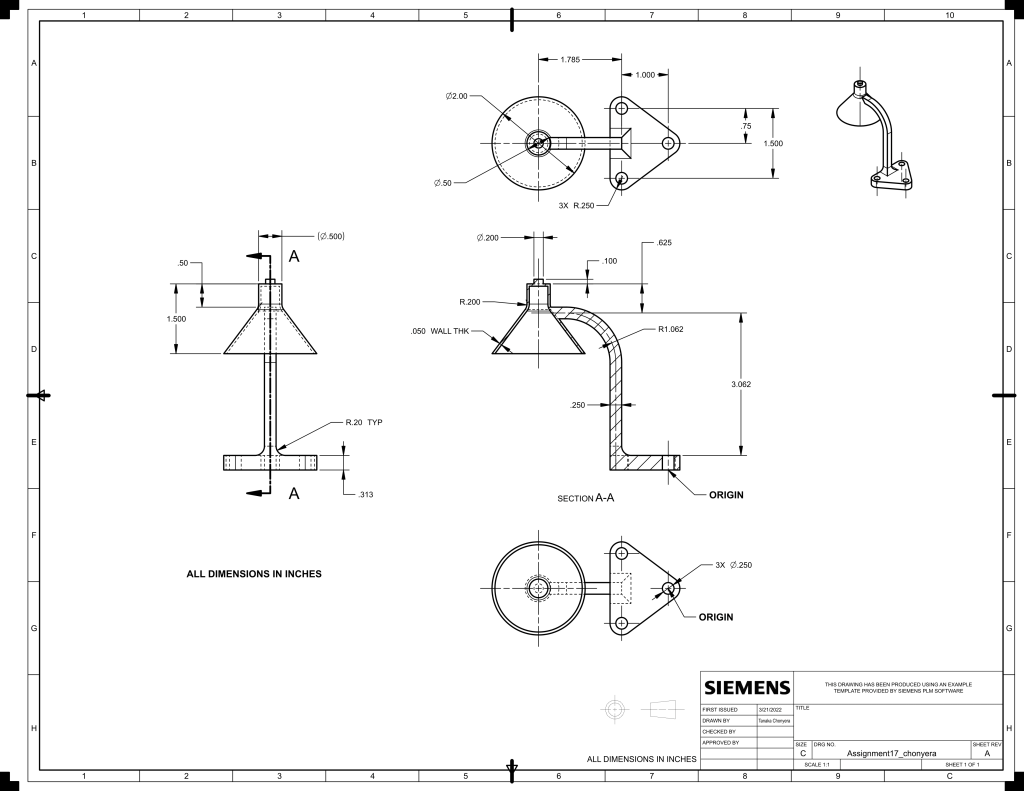

I designed (in Siemens NX) and manufactured High Voltage Divider for use in Collinear Laser Spectroscopy Experiment identifying laser spectrum of radioactive nuclei.

I analyzed and processed output data from high voltage divider using Python to determine divider ratio and compare performance with stock high voltage divider from the National Metrology Institute of Germany.

Research, Electrical Engineering & Nuclear Physics: Video of High Voltage divider Development Process – Facility For Rare Isotope Beams

Research, Electrical Engineering & Nuclear Physics: 2022 Undergraduate Research and Arts Forum Presentation – Michigan State University

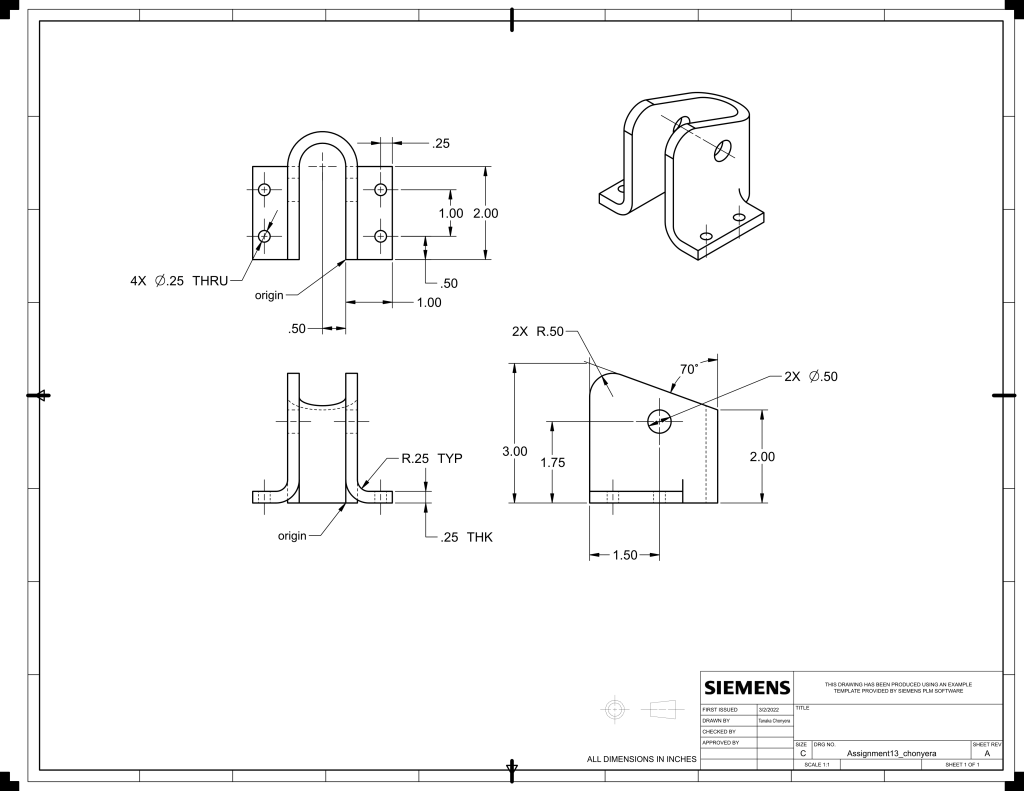

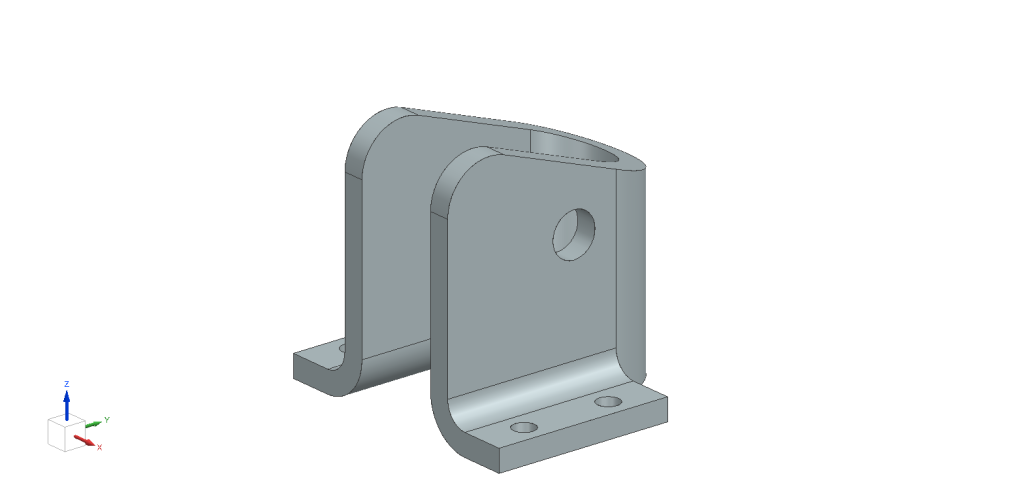

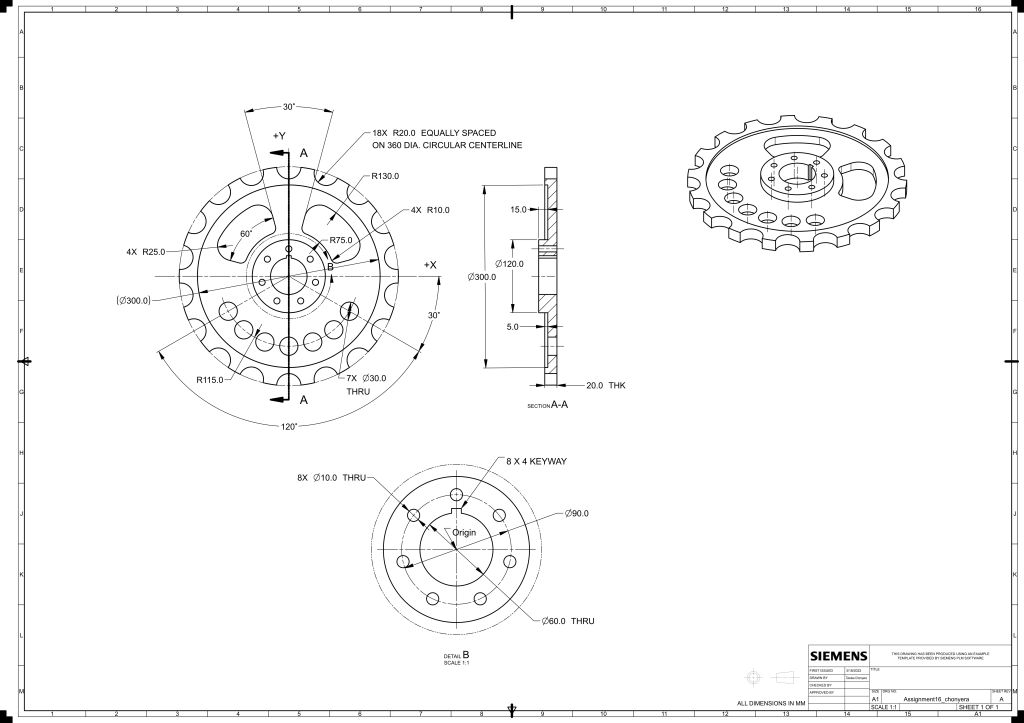

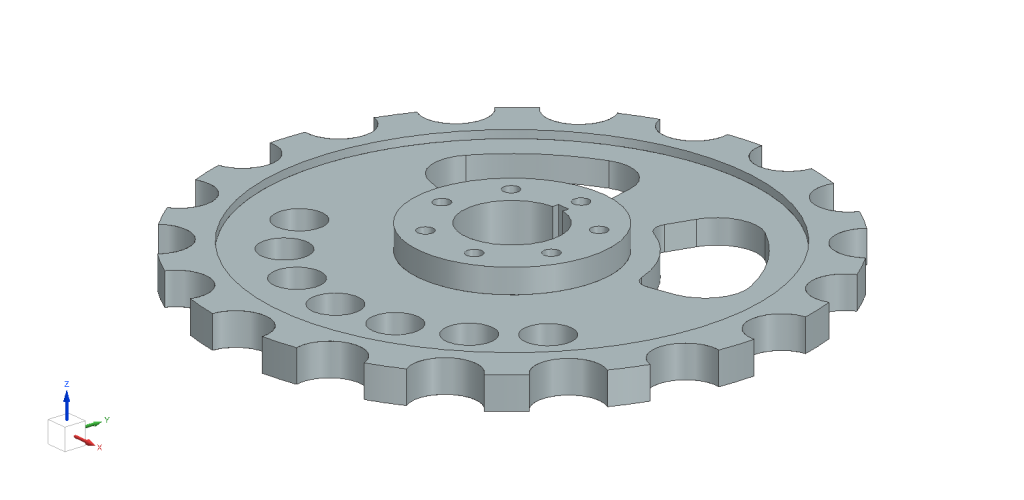

Mechanical Engineering: Computer Aided Design (CAD) – Facility For Rare Isotope Beams

Mechanical Engineering: Computer Aided Design (CAD) – Michigan State University

Mechanical Engineering & Renewable Energy: Parabolic Solar Array – Maru-a-Pula

Botswana is the country with perhaps the greatest potential for solar power in the world. Yet, it imports most of it’s power from South Africa. I designed and built this proof of concept generator as a proof of concept for affordable renewable energy with rural farmers as the target market.

The mirrors reflect sunlight onto a matte black copper pipe the is filled with either heating fluid or water. If water is used, it is fed into the pipe, closed off and heated until high pressure steam is produced. This is then released and used to turn a turbine and generate electricity.

If heating fluid is used, it can be cycled in closed loop system and used as a heater.

Computer Science & Programming: Coursework & Projects – Michigan State University

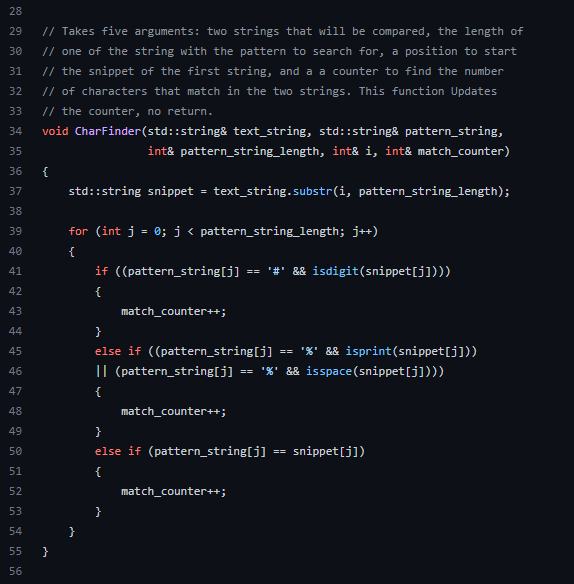

The bulk of my experience comes from college coursework. I’ve taken classes that covered all basic and many advanced programming concepts such as recursion, algorithms and data structures and object-oriented programming in both C++ and Python. I have a good understanding of computer architecture and how written code is translated into machine language having used low-level languages like C, C++ and theoretically, assembly.

My college classes are heavily project based. Using C++, we had many projects that required use of concepts learned in class like static and dynamic memory allocation and user defined classes to make a rudimentary cryptocurrency exchange and bank account. Projects in Python included utilizing file processing techniques to make a Pokémon game and extract data from csv files and display them in easily interpretable graphs. I have learned and understand concepts including: space and time complexity (Big O notation), finite state automatons, number theory, proofs and propositional and predicate logic.

Mechanical & Automotive Engineering: Formula SAE – Michigan State University

As part of Michigan State University’s Formula Racing team, I have machined components for radiator mounts and suspension systems using manual mill for our new monocoque design.

I researched air filter alternatives for improvement in air-to-fuel ratio, power delivery and combustion efficiency. I also researched alternative front wing designs to prevent failure caused by excessive aerodynamic load.